Online Magazine

Recent Posts

- Safeguard your Cellphone Photos

- Black & White to Color – Instantly

- Wearing Many Hats

- Video Roundup

- Rescuing Your Blurry Pictures

- Showing Their Age

- What is Your Angle?

- Panorama Photos

- Humorous Photos

- Close Ups

- Fisheye Pictures

- Photo Antiquities

- Printing Big

- Appreciating Scale

- Celebrity Sightings

Tags

More Places to Go

- Free "How-To" Books “How To” books for popular cameras 0

- Vist Us on Facebook keep in touch with us on Facebook 2

Archives

- July 2023 (1)

- March 2023 (2)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- September 2022 (8)

- August 2022 (9)

- July 2022 (1)

- June 2022 (1)

- June 2021 (1)

- May 2021 (1)

- March 2021 (5)

- February 2021 (4)

- January 2021 (2)

- April 2019 (1)

- March 2019 (1)

- February 2019 (1)

- October 2018 (2)

- April 2018 (1)

- March 2018 (4)

- February 2018 (1)

- November 2017 (1)

- August 2017 (1)

- June 2017 (1)

- April 2017 (1)

- March 2017 (5)

- February 2017 (2)

- January 2017 (1)

- October 2016 (1)

- September 2016 (1)

- August 2016 (1)

- July 2016 (1)

- May 2016 (1)

- April 2016 (1)

- March 2016 (2)

- February 2016 (1)

- January 2016 (2)

- December 2015 (1)

- November 2015 (1)

- October 2015 (3)

- April 2015 (1)

- March 2015 (5)

- February 2015 (1)

- January 2015 (4)

- December 2014 (2)

- November 2014 (5)

- October 2014 (2)

- September 2014 (1)

- August 2014 (2)

- July 2014 (1)

- May 2014 (1)

- April 2014 (5)

- March 2014 (5)

- December 2013 (2)

- November 2013 (18)

- October 2013 (1)

- September 2013 (1)

- August 2013 (1)

- July 2013 (1)

- June 2013 (3)

- May 2013 (1)

- April 2013 (2)

- March 2013 (1)

- February 2013 (1)

- January 2013 (1)

- December 2012 (1)

- November 2012 (2)

- October 2012 (2)

- September 2012 (5)

- August 2012 (2)

- July 2012 (1)

- June 2012 (1)

- May 2012 (1)

- April 2012 (4)

- March 2012 (1)

- February 2012 (1)

- January 2012 (3)

- December 2011 (1)

- November 2011 (3)

- October 2011 (1)

- September 2011 (2)

- August 2011 (2)

- June 2011 (3)

- May 2011 (4)

- April 2011 (8)

- March 2011 (8)

- February 2011 (10)

- January 2011 (6)

- December 2010 (11)

- November 2010 (14)

- October 2010 (6)

- September 2010 (12)

- August 2010 (2)

- July 2010 (4)

- June 2010 (3)

- May 2010 (1)

- April 2010 (1)

- March 2010 (2)

- February 2010 (1)

- January 2010 (1)

- December 2009 (1)

- November 2009 (2)

- October 2009 (2)

- September 2009 (1)

- August 2009 (3)

- July 2009 (2)

- June 2009 (1)

- May 2009 (2)

- April 2009 (1)

- March 2009 (2)

- February 2009 (1)

- January 2009 (3)

MakerBot and 3D Printing

14th November 2013

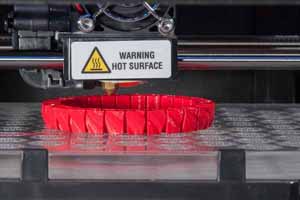

3D Printers will soon be Commonplace

At this year’s Consumer Electronics Show, I spent some time scouting out 3D printers. These are devices that can build or construct a three-dimensional solid object. For a couple of months, I studied the literature and researched several models via the Internet.

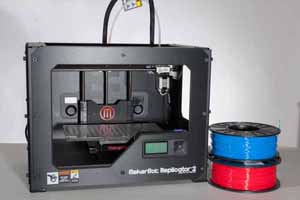

A couple of months later while I was in New York City, I stopped by a store in downtown Manhattan. It’s not your usual store – it’s for “techies” like me. MakerBot, a manufacturer of 3D printers had opened a store right in Manhattan. If the staff could prove to me that using their Replicator 2 was simple, I’d buy one.

And that’s exactly what happened. A ten minute demo convinced me that I’d be able to operate their technological marvel. I ordered one to be shipped back to Grand Rapids and it was waiting for me by the time I returned home.

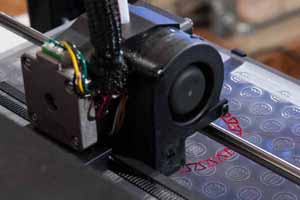

I found the technology in this device to be amazing and thought that some of you might want to know how it works.

Why do I have one?

The short answer is that I want to understand the technology and learn the uses of 3D printing. I believe these devices are going to become very commonplace soon. The Replicator 2 sells for about $2500, a relatively modest price. But they are already they are widely used in industry with companies eager to earn significant savings when making prototypes of their products.

Coincidentally, I received an email from MakerBot this morning. They are starting a campaign to “put a 3D printer into every school”. If you brush aside the fact that the promotion is self-serving, the idea of educating our younger generation about this amazing technology is certainly worth considering.

MakerBot oversees a rather large “library” of 3D designs called the Thingiverse. It has more than 100,000 items to choose from and most of the designs are free. You can download the designs and run it through their Makerware software (included with the Replicator 2) to convert for printing. Copy the program to the SD-card and you’re ready to construct a new 3D design.

For more information about the Replicator 2, please visit MakerBot.

Written by: Arnie Lee

Arnie,

Thank you. I have been following 3d printing now for going on three years and have seen an enormous increase in focus and interest.

I started three years ago to register domain names related to 3D Printing and 3D Scanning and now own 450 + domain properties.

Some of my domain names are The3DPrinter.com, Consumer3DPrinting.com, Jewelry3dPrinting.com, Metal3DPrinter.com, 3DAttire.com, FashionIt3D.com, FashionIn3D.com, 3DSilver.com, 3DPrintingInstitute.com, 3DNAND.com, 3DVertical.com, 3DPrintLink.com, 3DScanPrint.com, Shop3DScanners.com, The3DScanner.com… etc.

With the expiration of some key patents related to metal 3d printing in early 2014, the momentum of 3d printing will eccelerate.

Comment by Robert McLean — November 14, 2013 @ 6:40 am