Online Magazine

Recent Posts

- Safeguard your Cellphone Photos

- Black & White to Color – Instantly

- Wearing Many Hats

- Video Roundup

- Rescuing Your Blurry Pictures

- Showing Their Age

- What is Your Angle?

- Panorama Photos

- Humorous Photos

- Close Ups

- Fisheye Pictures

- Photo Antiquities

- Printing Big

- Appreciating Scale

- Celebrity Sightings

Tags

More Places to Go

- Free "How-To" Books “How To” books for popular cameras 0

- Vist Us on Facebook keep in touch with us on Facebook 2

Archives

- July 2023 (1)

- March 2023 (2)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- September 2022 (8)

- August 2022 (9)

- July 2022 (1)

- June 2022 (1)

- June 2021 (1)

- May 2021 (1)

- March 2021 (5)

- February 2021 (4)

- January 2021 (2)

- April 2019 (1)

- March 2019 (1)

- February 2019 (1)

- October 2018 (2)

- April 2018 (1)

- March 2018 (4)

- February 2018 (1)

- November 2017 (1)

- August 2017 (1)

- June 2017 (1)

- April 2017 (1)

- March 2017 (5)

- February 2017 (2)

- January 2017 (1)

- October 2016 (1)

- September 2016 (1)

- August 2016 (1)

- July 2016 (1)

- May 2016 (1)

- April 2016 (1)

- March 2016 (2)

- February 2016 (1)

- January 2016 (2)

- December 2015 (1)

- November 2015 (1)

- October 2015 (3)

- April 2015 (1)

- March 2015 (5)

- February 2015 (1)

- January 2015 (4)

- December 2014 (2)

- November 2014 (5)

- October 2014 (2)

- September 2014 (1)

- August 2014 (2)

- July 2014 (1)

- May 2014 (1)

- April 2014 (5)

- March 2014 (5)

- December 2013 (2)

- November 2013 (18)

- October 2013 (1)

- September 2013 (1)

- August 2013 (1)

- July 2013 (1)

- June 2013 (3)

- May 2013 (1)

- April 2013 (2)

- March 2013 (1)

- February 2013 (1)

- January 2013 (1)

- December 2012 (1)

- November 2012 (2)

- October 2012 (2)

- September 2012 (5)

- August 2012 (2)

- July 2012 (1)

- June 2012 (1)

- May 2012 (1)

- April 2012 (4)

- March 2012 (1)

- February 2012 (1)

- January 2012 (3)

- December 2011 (1)

- November 2011 (3)

- October 2011 (1)

- September 2011 (2)

- August 2011 (2)

- June 2011 (3)

- May 2011 (4)

- April 2011 (8)

- March 2011 (8)

- February 2011 (10)

- January 2011 (6)

- December 2010 (11)

- November 2010 (14)

- October 2010 (6)

- September 2010 (12)

- August 2010 (2)

- July 2010 (4)

- June 2010 (3)

- May 2010 (1)

- April 2010 (1)

- March 2010 (2)

- February 2010 (1)

- January 2010 (1)

- December 2009 (1)

- November 2009 (2)

- October 2009 (2)

- September 2009 (1)

- August 2009 (3)

- July 2009 (2)

- June 2009 (1)

- May 2009 (2)

- April 2009 (1)

- March 2009 (2)

- February 2009 (1)

- January 2009 (3)

Affordable 3D Printer by New Matter

07th November 2017

I’ve been a tech junkie for a very long time. It seems that whenever new technology appears, I’m fairly quick to try it out.

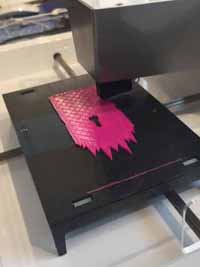

Several years ago, I bought a MakerBot 3D printer. Early adopters know that purchasing new technology is usually expensive – this model had a price tag just north of $2000. Using it, I’ve learned the mechanics of how these amazing devices turn long rolls of plastic filament (PLA) into very detailed solid models. The prize is a collection of plastic models that adorn my office and the house. To be honest, I haven’t had a need for additional 3D models, so the MakerBot has been sitting unused for the past few months.

At this past January’s Consumer Electronics Show I ran across a couple of new 3D printers. And while the technology is no longer new, the prices of several of the printers are now within the grasp of many more consumers. My interest in a second 3D printer was motivated by my curiosity about the quality of the finished models compared to the more expensive MakerBot from a couple of years ago.

New Matter is a relatively new manufacturer that makes the MOD-t 3D printer. I purchased one directly from New Matter bundled with additional filament and accessories for $350 – a huge price difference vs. the MakerBot from a few years ago.

I’m impressed with the quality of the finished 3D models, especially at the rock-bottom $$300 price. For more information, please visit New Matter.

Those Boxes of Old Photos

10th June 2017

Scanning Made Easy with the Epson FF-640

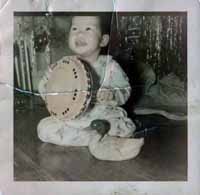

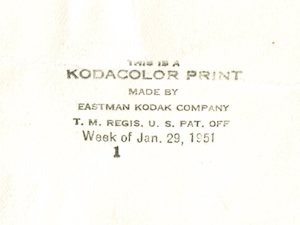

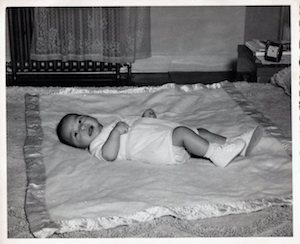

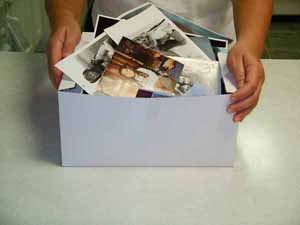

If you’re old enough to drink (alcohol that is), then you may remember the shoebox in the closet stuffed with family photos. They sit there collecting dust until someone brings up a past event that has you digging through hundreds of prints looking for the time that Uncle John took you fishing and you caught your first keeper.

|

|

|

|

|

|

|

|

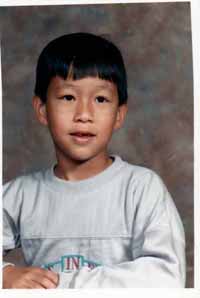

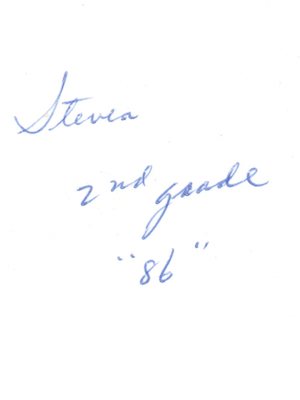

Our family has been taking and collecting photographs since the 1920s. As the unofficial designated keeper of the archives, I’ve been slowly scanning these photos with the goal of organizing, documenting and distributing them to the many relatives and friends among our (very large) extended family.

|

|

|

| About the year 2000 I acquired my first flat bed scanner similar to this one.

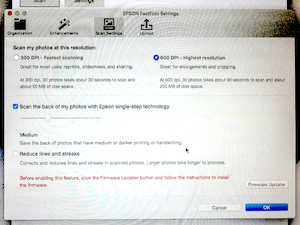

Although a flat bed produces good quality digital images, it is slow and laborious to operate. Each photo is carefully placed on the glass top, the cover is closed and then the computer is instructed to start the scan. Owing to my lack of patience, I can scan only a couple of dozen prints using the flat bed at one sitting. Afterwards, I have to take a break. At this pace, it will be a long time to complete my archiving obligation. NOTE: The flat bed scanner to the right is a newer advanced model that can produce very high resolution digitized images from your photos. It can also produce digitized images from film negatives (do you remember film?) and transparencies (slides). For the many shoeboxes full of old photos that I have to organize, I’ve decided that speed is more important than high resolution. At this year’s WPPI Conference and Expo, I found a solution that is now helping me make progress dealing with the thousands of prints that have been collecting dust in the closet – the Epson FF-640 FastFoto scanner. |

|

|

|

|

|

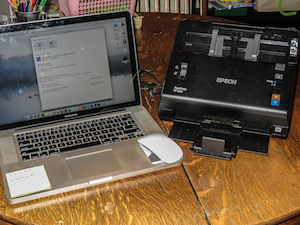

The FF-640 scanner connects to your computer with a USB-cable. The computer here is a MacBook but the scanner is compatible with Windows PCs as well.

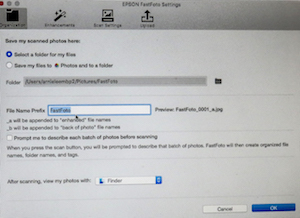

Photos are stacked into the feeder face down. The guides on the feeder are adjustable and accommodate up to twenty or so photos of the same width. The Epson software lets you specify the level of resolution – either the lower 300 dpi or the higher 600 dpi. While you can save hard disk space by using the 300dpi setting, I’ve always scanned at the 600 dpi setting since I’m not concerned about conserving hard disk space. You can also select a folder for storing the scanned images. |

|

|

|

|

|

|

|

|

You can start scanning your stack of photos by clicking on the FastFoto software start button. Alternatively you can press the blue button on the FF-640. This is another nice feature since you can take as much time to load subsequent groups of photos into the scanner without having to reset the software. |

When you’ve completed scanning one or more stacks of photos, the FastFoto software displays the digital images on screen. The software lets you enhance the brightness and contrast, remove red eye and restore faded colors of the original photo if you’d like to save editing time afterwards. |

|

|

|

The FF-640 sells for about $650 – a considerable investment. However, I’m thoroughly happy with this scanner. It has saved me countless hours of time on my quest to archive the thousands (tens of thousands) of family photographs.

For more information, please visit Epson.

Seen at WPPI – Quality Printing Papers

12th March 2017

Some Day My Prints Will Come

For decades I was schooled in conventional (film) photography. So it’s natural that I am a lover of photographic prints. And although I enjoy the convenience and portability of electronic display devices, I simply prefer to view my work on hardcopy prints.

Last last year, I ordered a large format printer – the Epson P800. Normally it makes prints up to size 17″ x 22″. Add a roll paper feeder and it can produce enormous panoramas up to 129″ wide. Since the printer was in high demand at the time, my waiting time was about a month for delivery.

When I finally received the printer, I was preoccupied with a lot of other work. To ensure that the printer was working properly I used to make only two or three prints and then set it aside.

Jump ahead two months and I’m attending the WPPI Conference & Expo. I think to myself that I should learn about printing papers to get the best results from the investment in my Epson P800. And so at WPPI I stop at several makers of fine art papers to get educated.

|

|

|

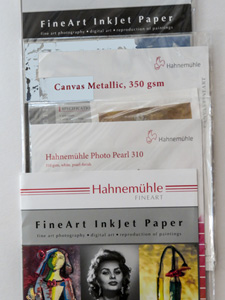

| Hahnemuhle is a German based company that offers a wide variety of papers. I look at their large catalog and am stumped by some of the terminology. So I start asking questions.

What is baryta paper? I’m told that it is paper coated with barium sulphate, a substance used on traditional photographic paper. When baryta paper is used for inkjet printing, it supposedly reproduces the effect of silver halide processing. Many of the paper descriptions include a gsm value. I find that gsm is an acronym for grams per square meter. Thus a square meter of Canvas Metallic 350 gsm paper is heavier than FineArt Baryta Satin 3500 gsm paper. I am also curious about paper with the rag description. I learn that this paper is made from cotton linters or rags and is superior to wood-based paper. |

|

The helpful representative left me with this sampler – a collection of their fine art photography papers and other helpful literature. For more information please visit Hahnemuhle. |

|

|

|

|

| Namhoon Kim is the Marketing Manager for Durico Media. The company is based in southern California. As you can see from the below photograph, they have a rather large selection of papers.

I helped myself to about a dozen of their print samples all on different paper stock. I find that the samples are the only way to determine if a paper is suitable for one of my prints. Reading a catalog description does not give me the know-how to select a paper – I require hands-on to feel the surface and a sample photograph to give me the visual feedback. For more information, please visit Durico Imaging. |

|

|

|

|

|

|

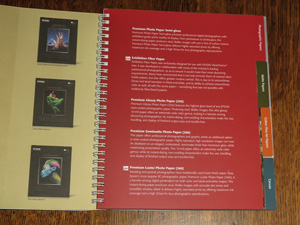

| Epson is probably best known as a manufacturer of printers. They also are a large producer of high quality printing papers.

My visit to Epson is to find out more about their printing papers and luckily I am handed a “Print Sample Guide” to take with me. It has their complete line of papers with printed samples: photographic, matte, cotton fine art and canvas. Before I depart the representative shows me their new software Epson Print Layout. This app is for users of Epson professional printers and provides a convenient and elegant way to organize, set up and print your images. If you’re a user of a high end Epson printer, you can download a copy of the Epson software from here. For more information about their papers, please visit Epson. |

|

|

|

|

|

|

| Paperwise, I’m 3 for 3. I walked away with samples from three different manufacturers. So with samples in hand, I am prepared to make my paper choices. Now I’m ready to fire up that printer that has been sitting idle waiting for me. | |

Written by: Arnie lee

« Older Posts — Newer Posts »